Page 26 - Oct24

P. 26

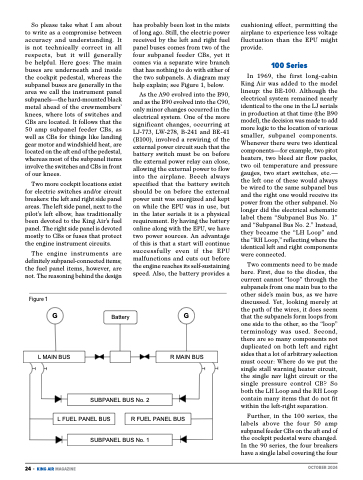

So please take what I am about to write as a compromise between accuracy and understanding. It is not technically correct in all respects, but it will generally be helpful. Here goes: The main buses are underneath and inside the cockpit pedestal, whereas the subpanel buses are generally in the area we call the instrument panel subpanels—the hard-mounted black metal ahead of the crewmembers’ knees, where lots of switches and CBs are located. It follows that the 50 amp subpanel feeder CBs, as well as CBs for things like landing gear motor and windshield heat, are located on the aft end of the pedestal, whereas most of the subpanel items involve the switches and CBs in front of our knees.

Two more cockpit locations exist for electric switches and/or circuit breakers: the left and right side panel areas. The left side panel, next to the pilot’s left elbow, has traditionally been devoted to the King Air’s fuel panel. The right side panel is devoted mostly to CBs or fuses that protect the engine instrument circuits.

The engine instruments are definitely subpanel-connected items; the fuel panel items, however, are not. The reasoning behind the design

Figure 1

has probably been lost in the mists of long ago. Still, the electric power received by the left and right fuel panel buses comes from two of the four subpanel feeder CBs, yet it comes via a separate wire branch that has nothing to do with either of the two subpanels. A diagram may help explain; see Figure 1, below.

As the A90 evolved into the B90, and as the B90 evolved into the C90, only minor changes occurred in the electrical system. One of the more significant changes, occurring at LJ-773, LW-278, B-241 and BE-41 (B100), involved a rewiring of the external power circuit such that the battery switch must be on before the external power relay can close, allowing the external power to flow into the airplane. Beech always specified that the battery switch should be on before the external power unit was energized and kept on while the EPU was in use, but in the later serials it is a physical requirement. By having the battery online along with the EPU, we have two power sources. An advantage of this is that a start will continue successfully even if the EPU malfunctions and cuts out before the engine reaches its self-sustaining speed. Also, the battery provides a

cushioning effect, permitting the airplane to experience less voltage fluctuation than the EPU might provide.

100 Series

In 1969, the first long-cabin King Air was added to the model lineup: the BE-100. Although the electrical system remained nearly identical to the one in the LJ serials in production at that time (the B90 model), the decision was made to add more logic to the location of various smaller, subpanel components. Whenever there were two identical components—for example, two pitot heaters, two bleed air flow packs, two oil temperature and pressure gauges, two start switches, etc.— the left one of these would always be wired to the same subpanel bus and the right one would receive its power from the other subpanel. No longer did the electrical schematic label them “Subpanel Bus No. 1” and “Subpanel Bus No. 2.” Instead, they became the “LH Loop” and the “RH Loop,” reflecting where the identical left and right components were connected.

Two comments need to be made here. First, due to the diodes, the current cannot “loop” through the subpanels from one main bus to the other side’s main bus, as we have discussed. Yet, looking merely at the path of the wires, it does seem that the subpanels form loops from one side to the other, so the “loop” terminology was used. Second, there are so many components not duplicated on both left and right sides that a lot of arbitrary selection must occur: Where do we put the single stall warning heater circuit, the single nav light circuit or the single pressure control CB? So both the LH Loop and the RH Loop contain many items that do not fit within the left-right separation.

Further, in the 100 series, the labels above the four 50 amp subpanel feeder CBs on the aft end of the cockpit pedestal were changed. In the 90 series, the four breakers have a single label covering the four

G Battery G

L MAIN BUS

SUBPANEL BUS No. 2

L FUEL PANEL BUS R FUEL PANEL BUS

R MAIN BUS

SUBPANEL BUS No. 1

24 • KING AIR MAGAZINE

OCTOBER 2024